News & Events More |

Post-WarAs early as the 1946 B.C.F.G.A. Convention, D. McNair, Tree Fruits' sales manager, warned that the return to an open market when wartime controls were lifted could hurt fruit returns severely. During the war the restrictions on imports of bananas, citrus, and foreign apples had given B.C. fruit an easy market among Canadian consumers with increased buying power but very little to spend their money on. Consumers had not been very discriminating about quality and price, but that would change as other goods became available.

The problem of quality was particularly worrisome. With high prices for even low grade apples during the war, growers were using much more fertilizer (the increase between 1940 and 1945 was 250% in some areas and up to 750% in others) and letting their trees grow bushy in order to maximize tonnage. This meant that quality and keeping ability dropped. The proportion of "Cee" grade in the 1940 apple crop was 16.5%; by 1945 it had doubled to 32.65%, and 48.5% of Macs went Cee. The experts recommended cutting down on fertilizer. But with a pooling system based upon the spreads between grades that had existed before the war, even though the post-war market was considerably less forgiving, it still paid growers to pump in the nitrogen and aim for volume rather than quality.

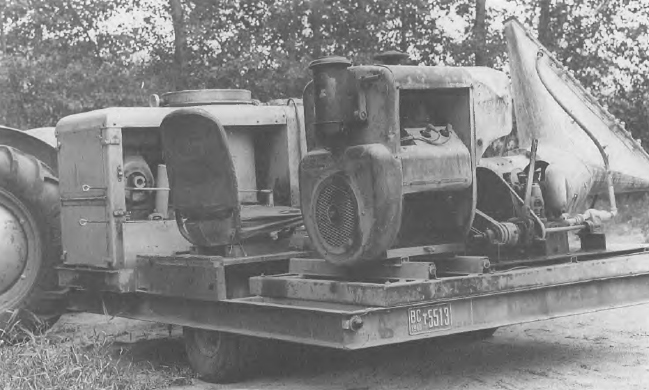

Vignette: The Modern Orchard SprayerIn 1946, with the advent of new spray materials, Dr. James Marshall of the Summerland Research Station began to look for a better method to apply them. What was needed was some automatic way to distribute the spray which would be faster and less labour-intensive than the current system of dousing each tree with hoses and spray wands.

A steam sprayer made by the Besler Corporation in California was tested but gave only fair results, since it could be used only under the most favourable conditions. During the winter of 1946, Frank Owen, a technician at the Canadian Army machine shops at Suffield, Alberta, built an experimental low-volume sprayer to specifications Dr. Marshall had dreamed up. In the spring he delivered the "Rube Goldberg", "a truly incredible contraption. It was a mass of gears. Motors, belts, blowers, pumps and valves protruded insanely above the four airwheels on which it sat." Fortunately, despite its appearance, the experimental machine worked as intended. It could produce either a steam-mist or a hydraulic pressure spray-mist which would be propelled onto the trees at about a hundred miles per hour by the airstream from a large fan. By varying the temperature of the steam, thus changing the size of the droplets produced, the experimenters determined the optimum droplet size for concentrated spray application; if droplets were too fine, the spray fog was uncontrollable and drifted; if too coarse, it covered unevenly and injured trees.

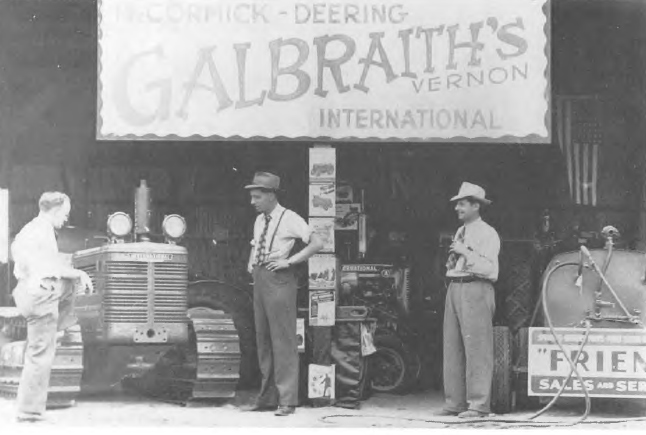

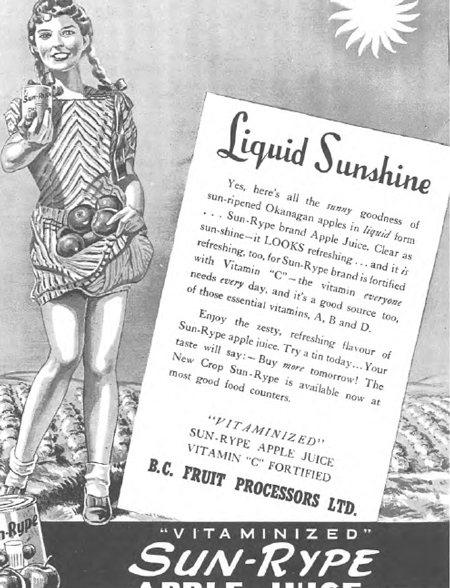

After much experimentation, the optimum size was determined to be approximately fifty microns. The next stop was to adjust the hydraulic system, by changing the pump-pressure and the size of swirl-plates and nozzles, to give a droplet of that size, so spraying could be done without the cumbersome inconvenience of generating steam. The design information gained was released to manufacturers. The first commercial lowvolume automatic concentrate sprayer, the "Turbomist" was produced in 1949 by a Penticton firm; other Okanagan manufacturers soon put out their own versions. The new machines reduced the labour-cost of spraying by three-quarters and the materials-cost by about one-fifth; three times the orchard acreage could be served by an airblast sprayer as by an old hose-type dilute sprayer. No wonder that by 1957, of all the spraying operations of the B.C. tree fruit industry, ninety per cent was done by air-blast machines.2 Today spray-guns are used only occasionally, for pinpoint or touchup jobs where selected trees or parts of trees in a block are to be covered. The 1946 B.C.F.G.A. convention tackled the problem of low quality fruit. It passed a resolution that processing of cull fruit should be undertaken by the industry as a whole on behalf of the growers, and the Executive was instructed to form a corporation for that purpose. British Columbia Fruit Processors Ltd., thus formed, bought out the existing processing plants, and operated them starting with the 1946 season. The needed capital, $275,000, was borrowed on a low-interest bank loan and a revolving capitalization system was set up, whereby the bank was repaid in five annual payments drawn from the company's income. Each grower received a certificate for his share of the money diverted. After those initial five years, the oldest year's certificates were paid off annually and new ones were issued to current growers. Even in its initial 1946 season, B.C. Fruit Processors handled one-eighth of the apple crop, and its importance as a means of keeping poor quality fruit off the market increased almost every year after that.

The 1947 Convention also made an effort to wrestle with the causes of poor quality, passing a resolution calling for a phasing out of the fixed spread between grades now that the wartime controls were being lifted. It also called for the revision of the Five-Year-Average Scale used in distributing fruit pools. This revision established more realistic conditions by annually deleting one of the five pre-war years, 1935-39, currently used in setting the scale, and replacing it with sales returns from the latest post-controls year. In general, growers were satisfied. Although the Wartime Prices and Trade Board disappeared in 1947, the federal government instituted an Austerity Program, designed to conserve foreign exchange, which drastically limited imports of foreign fruit. So prices, while drifting down somewhat from wartime highs (the 1948 apple crop returned an average of $1.16 per bushel to growers), remained acceptable in light of higher production. Growers, protected to a considerable degree from the demands of the marketplace by the fixed system of pooling, were very slow to adjust their production to market demands for higher quality and a changed mix of varieties. Contact Us Hours: 9am - 4pm weekdays. t: 250-762-5226 |